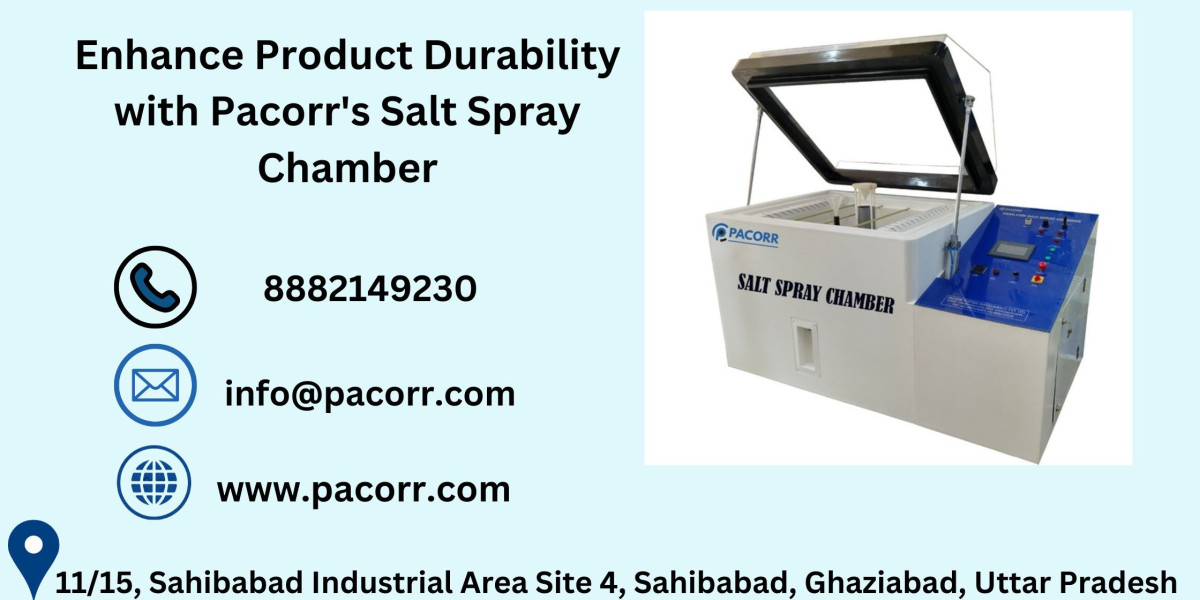

If you’re considering purchasing or learning about salt spray chambers, you’ve come to the right place. At Pacorr.com, we provide cutting-edge solutions tailored to meet the demands of quality assurance and product longevity.

What is a Salt Spray Chamber?

A Salt Spray Chamber is a controlled environment testing apparatus designed to simulate corrosive conditions. By exposing materials or coatings to a salt-laden mist, the chamber accelerates corrosion, enabling manufacturers to assess the durability of their products in a fraction of the time it would take under natural conditions.

How Does a Salt Spray Chamber Work?

The chamber operates by creating a fine mist of salt solution (commonly sodium chloride) within a sealed environment. Specimens are placed inside the chamber, and the mist is sprayed continuously or intermittently to mimic long-term exposure to corrosive conditions.

The test duration can vary based on the material’s expected usage and the specific industry standards being followed, such as ASTM B117 or ISO 9227v.

Applications of Salt Spray Chambers

Salt spray chambers are widely used across industries for quality assurance and R&D purposes. Below are some of the key applications:

- Automotive Industry

Salt spray testing is crucial for evaluating the corrosion resistance of car parts, including body panels, undercarriages, and fasteners. This ensures vehicles maintain structural integrity and aesthetic appeal over time. - Aerospace Industry

Aircraft components, particularly those exposed to varying weather conditions, undergo rigorous salt spray testing to ensure safety and performance. - Marine Applications

In the marine industry, where exposure to salty environments is inevitable, salt spray chambers test the durability of materials like stainless steel, paints, and coatings. - Electronics and Electrical Components

Circuit boards, connectors, and other sensitive equipment are tested to ensure they resist corrosion, which could otherwise lead to system failures. - Construction Materials

Metals used in construction, such as roofing sheets and fasteners, are evaluated for their ability to withstand corrosive outdoor environments.

Features of a High-Quality Salt Spray Chamber

When choosing a Salt Spray Test Chamber, look for these key features:

- Durable Construction

The chamber should be made from corrosion-resistant materials such as fiberglass or reinforced plastics to ensure longevity. - Accurate Control Systems

Advanced control systems for temperature, humidity, and mist density ensure precise testing conditions. - Compliance with Standards

Ensure the chamber adheres to international testing standards like ASTM, ISO, and JIS. - Energy Efficiency

Modern chambers are designed to be energy-efficient while maintaining consistent performance. - User-Friendly Design

Features like easy specimen loading, digital displays, and automated test cycles enhance usability.

Why Choose Pacorr.com for Salt Spray Chambers?

At Pacorr.com, we are committed to providing world-class testing solutions to industries globally. Here’s what sets us apart:

- State-of-the-Art Technology: Our Salt Spray Chamber Price are equipped with the latest innovations, ensuring reliability and precision.

- Customizable Options: Whether you need a compact model for small-scale testing or a large chamber for industrial use, we have a solution for you.

- Expert Support: Our team of experts is always ready to guide you through the selection process, installation, and maintenance.

- Affordable Pricing: High-quality equipment doesn’t have to break the bank. We offer competitive prices without compromising on quality.

- Global Standards Compliance: All our products meet international testing standards, ensuring accurate and repeatable results.

Maintenance Tips for Salt Spray Chambers

To keep your salt spray chamber in optimal condition, follow these maintenance tips:

- Regularly clean the chamber and components to prevent salt build-up.

- Use distilled water for preparing the salt solution to avoid impurities.

- Check nozzles and spray mechanisms for blockages.

- Calibrate the equipment periodically to ensure accuracy.

- Store the chamber in a dry, well-ventilated area to prevent external corrosion.

Final Thoughts

Investing in a Salt Spray Chambers is crucial for industries that prioritize quality and durability. With its ability to simulate harsh environments, the chamber empowers manufacturers to produce corrosion-resistant products, ultimately boosting customer satisfaction and brand reputation.

At Pacorr.com, we pride ourselves on offering the best salt spray chambers tailored to your needs. Explore our range today and ensure your products stand the test of time.

Contact Us:

· Email: Info@pacorr.com

· Phone: 8882149230

· Visit our website at www.pacorr.com for more details on our testing instruments.